Drop FTTH cable patch product process.

SC/APC-SC /APCPre-Connectorized Optical Fiber Drop Cable produce precess

1. FTTH cable is cut into different lengths according to patch cord requirements, normally from 1m to 300m, but we can also cut according to other requirements. This is the first step in making the patch cord.

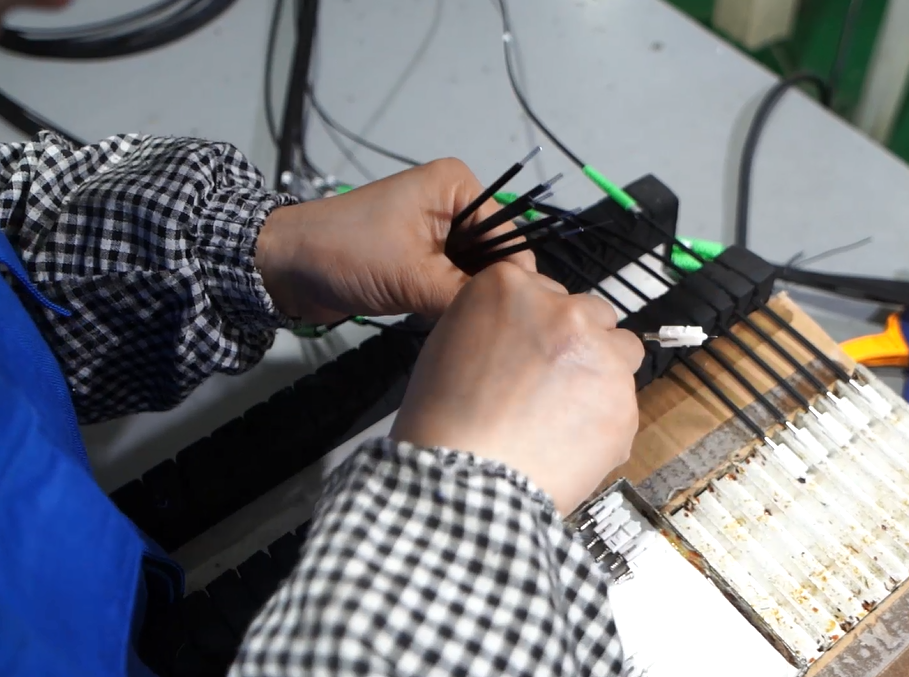

2. Put connector accessories in advance, before strippe out optic fiber.

3.Strip out the optical fiber and put on connector accessoires one by one. The length of the optical fiber should be set aside to facilitate subsequent operations.

4.hoting solidify: In order to ensure that the tensile strength of the joint can reach 120N, we need to fix the joint with special glue. Here, the curing time is one and a half hours. We extend the curing time and increase the tensile strength with the size of the iron parts.

5.Joint fixed:This process is very important, which determines the joint resistance strength. We have lengthened the size of the iron sheet and increased the amount of glue, so that the joint is more tensile.

6.Assemble connector

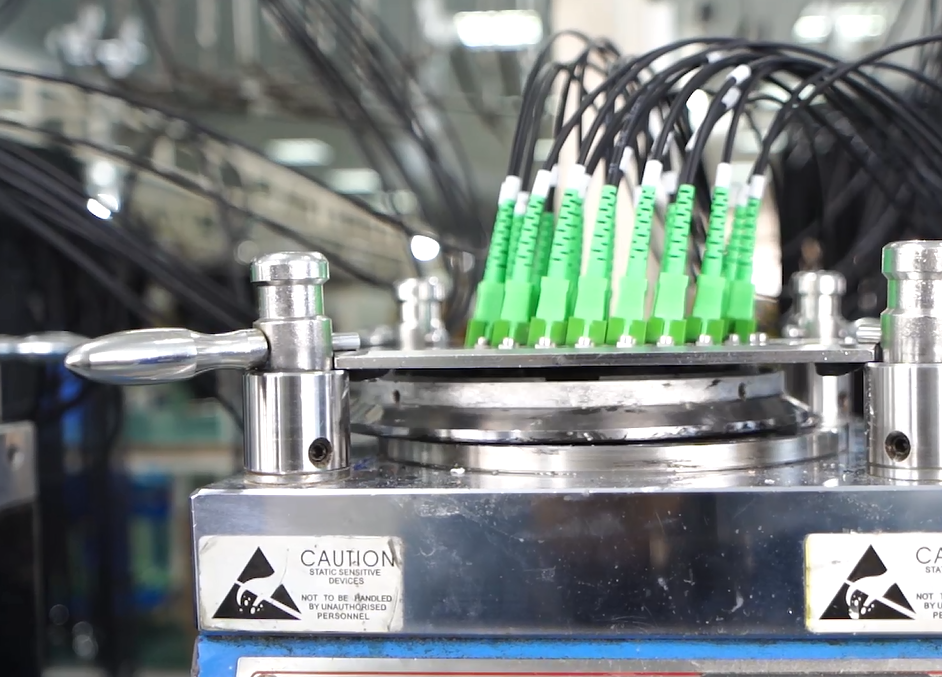

7.Grinding optic fiber end: SC/APC and SC/UPC Different grinding processes.Each optical fiber connector needs to be ground. The Angle of grinding varies with the connector.

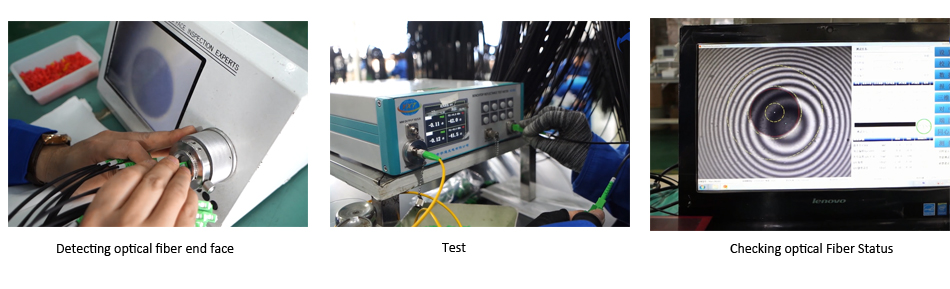

8. Check and test. Each connector requires 100% inspection end and test data

Test data details:

NO | Test | L≤20m | 20m<L≤50m | 50m<L≤100m | 100m<L≤200m |

a | Insertion loss(1310nm)1 | ≤0.3dB | ≤0.34dB | ||

b | Insertion loss(1550nm)2 | ≤0.3dB | ≤0.32dB | ||

c | Return Loss(UPC)3 | ≥47dB | ≥46dB | ≥45dB | ≥44dB |

d | Return Loss(APC)4 | ≥55dB | ≥51dB | ≥49dB | ≥46dB |

| 1More than 200m Insertion loss ( 1310nm):0.30dB + L×0.36dB/1000m2More than 200m Insertion loss ( 1550nm):0.30dB + L×0.22dB/1000m3More than 200m Return Loss ( UPC):≥40dB4More than 200m Return Loss (APC):≥40dB | |||||

相关阅读

Scan and add WeChat

Scan and add WeChat